This article is all about the comparison of Joisted Masonry vs Masonry Noncombustible. However, when you are constructing a building, you must choose the perfect type of construction according to your needs! Joisted masonry is the method that uses reliable masonry walls, wood, or steel for constructing floors and roofs.

Well, they are considered perfect due to their budget-friendly and fire-resistant power. Mostly, it is used in commercial buildings such as schools, shops, and others. Whereas, masonry Non-combustible uses materials such as concrete and metal throughout. However, they are also durable for resisting fire. Most proprietors choose it due to its enhanced safety and long-term savings.

So, by understanding such differences, you can make the right decision for your project and business. If you are short on budget, you can easily outsource masonry estimating services from a reliable company. They will provide you with a detailed cost analysis of every element in the project. However, the choice is all yours, but make sure to be smart because it can affect the building’s performance and safety. Without any further ado, let’s jump right into our main topic.

YOU NEED TO EXPLORE KEY DIFFERENCES BETWEEN JOISTED MASONRY VS MASONRY NONCOMBUSTIBLE TO MAKE THE RIGHT DECISION FOR YOUR CONSTRUCTION PROJECTS!

ISO Construction Classifications

The Insurance Services Office (ISO) classification system has divided the building categories into six construction types, which are based on fire resistance and material quality. However, these are developed by Insurance Services Office, Inc. (ISO) for deciding the rates to insure commercial properties.

Joisted Masonry (ISO Class 2/Construction Code 2)

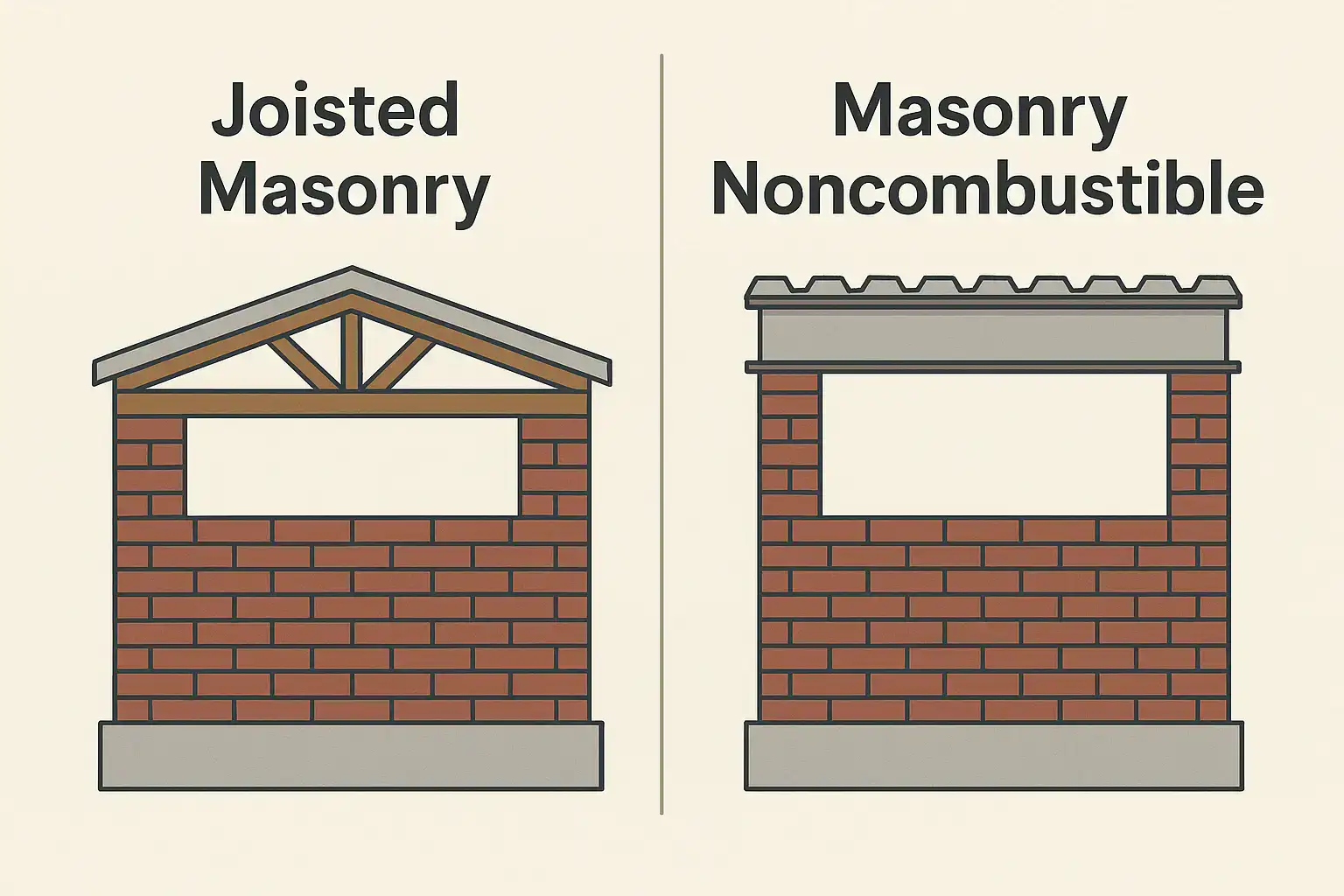

Joisted masonry construction involves exterior walls of masonry material like brick, concrete, gypsum block, hollow concrete block, etc. Whether you require it for residential, commercial, or industrial projects!

Plus, they also involve floors and roofs of combustible materials, typically wood or light-gauge steel joists. Its main features are as follows:

- The masonry materials are fire-resistant, which can bear the fire for up to 1 hour.

- In the flooring system, combustible materials such as wood and light-gauge steel are used.

- Well, there is a height limitation of four stories.

Masonry Noncombustible (ISO Class 4/Construction Code 4)

Masonry noncombustible construction includes the exterior walls of masonry with floors and roof made up of metal or other noncombustible materials. Due to which, it provides enhanced fire resistance. However, its key features are as follows:

- Its load-bearing is almost similar to joisted masonry.

- Noncombustible materials such as steel decking with concrete fill

- The roof is framed with the help of metal and non-combustible decking materials.

- It can be used for different building heights without any limitation.

Advanced Performance Analysis

Fire Resistance Performance

The major difference between these two types lies in the fire resistance performance.

Well, as told earlier, Joisted Masonry buildings offer moderate fire resistance, which can hold around one hour. Whereas, Masonry Non-Combustible constructions use non-combustible materials that offer enhanced fire resistance.

Critical Fire Performance Factors:

Combustible Component Vulnerability

Considering in joisted masonry construction, the use of combustible materials can speed up the fire spread and heat. So, this is a potential failure that does not exist in the latter one!

Structural Integrity Under Fire

Masonry noncombustible construction materials use unprotected steel for interior members of floors and roofs. However, they are more vulnerable at high temperatures.

Building Envelope Performance and Energy Efficiency

Thermal Performance Characteristics

The choice between Joisted Masonry vs Masonry Noncombustible highly depends on the building’s envelope performance.

Steel vs. Wood Framing Impact

Well, the material properties of the brackets result in up to a 70% difference between the corrected and uncorrected thermal transmittance values.

Vapor Permeability Differences

By comparing these two methods, Masonry noncombustible construction typically offers better moisture management due to the compatibility between steel framing and moisture barriers.

Economic Analysis and Decision Framework

Initial Construction Costs

Joisted Masonry is less expensive and quicker to install or construct. If you are on a tight budget, this is a good option for you! You can also hire experts from a reliable construction cost estimating firm and complete the projects under budget.

Maintenance and Replacement Costs

The noncombustible nature of Class 4 construction typically results in lower long-term maintenance costs. It is valid for mechanical and electrical systems.

IF YOU REQUIRE EXPERT COST ESTIMATION OPINIONS AND GET FLAWLESS ESTIMATES, HIRE OUR PROFESSIONALS AND COMPLETE PROJECTS SUCCESSFULLY!

Conclusion

However, the choice between Joisted Masonry and Masonry Noncombustible construction depends on your project requirement, climate, and other considerations. You need to look into various factors such as project budget and timeline constraints, occupancy type, and regulatory requirements, etc. As you all know that the use of digital tools has now become the most favourite part of building operations. So, property owners, developers, and design professionals must observe all the factors carefully to make informed decisions.