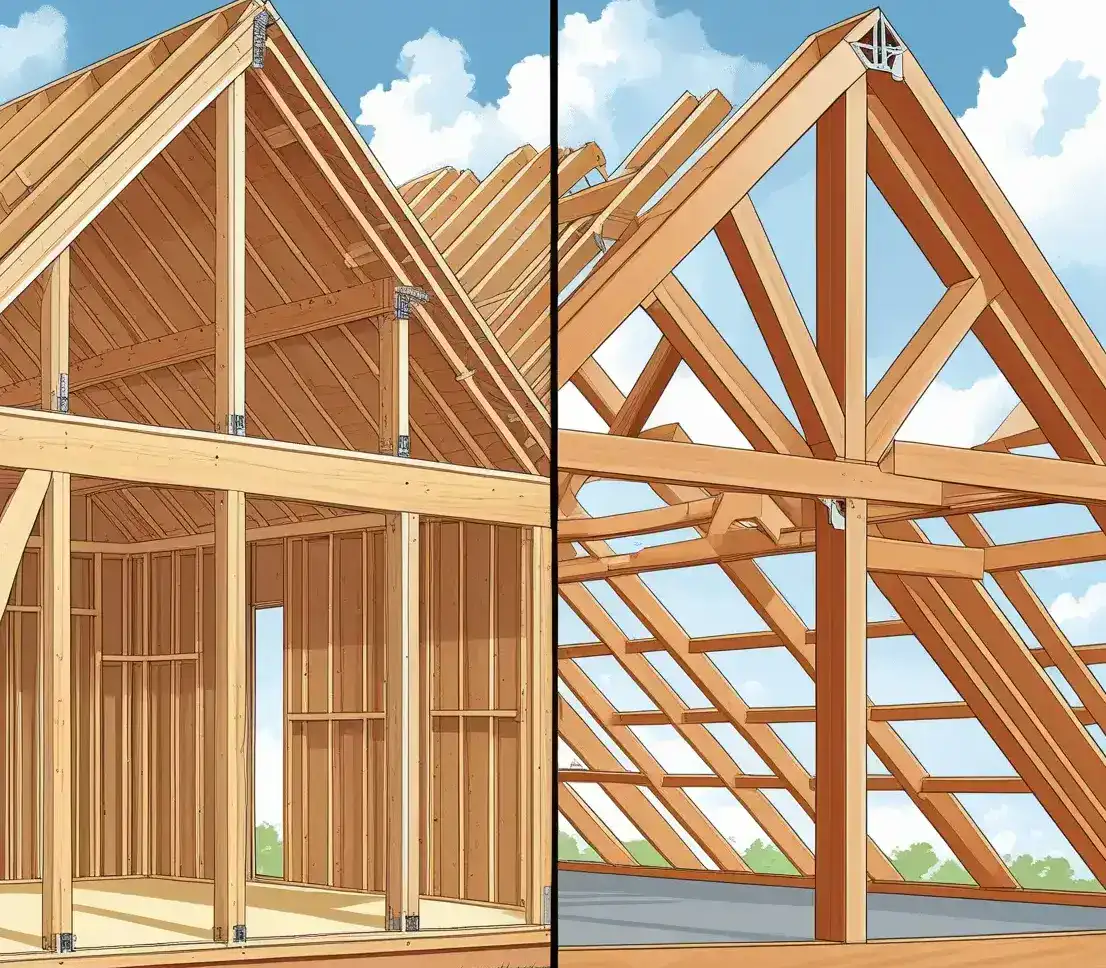

All over the construction world, there is often debate about Stick-Built vs. Truss-Built Roof use. Many contractors, homeowners, and builders are unsure which roofing method would be most effective. All of these systems are different, and selecting one can have a big impact on both cost and how easily it can endure.

Because of this, if you have a new construction or roof replacement project in mind, you should learn about both types in detail. You will learn the benefits and drawbacks of Stick-Built and Truss-Built roofs on this blog to make a better selection.

WANT TO KNOW WHICH ROOFING SYSTEM SUITS YOUR PROJECT BEST? STAY WITH SMA ESTIMATING LLC TO COMPARE STICK-BUILT VS. TRUSS-BUILT ROOFS AND DISCOVER COST-SAVING INSIGHTS!

Understanding the Stick-Built Roof

Stick-built roofs are made on-site, piece by piece, using dimensional lumber. Every rafter and ridge board is cut and installed manually. This method provides full customization. A stick-built roof can be adjusted to fit any floor plan or provide innovative details. Still, this flexibility requires doing some hard work. To build a stick-built roof, you need labor that takes more time than other roofs. This can increase your project’s cost.

Pros of Stick-Built Roofs

Homeowners who prefer custom design often lean toward stick-built roofs. It aligns well with complex architectural needs. There are several key advantages:

- Design Freedom: You can make custom roof pitches, overhangs, and shapes.

- Ideal for Complex Layouts: Works well for homes with multiple roof angles.

- Better for On-Site Changes: Allows easier adjustments during construction.

Cons of Stick-Built Roofs

From a roofing estimation perspective, stick-built designs can be harder to estimate due to variable labor and material needs. Despite the flexibility, stick-built roofs have downsides:

- Higher Labor Costs: It requires expert carpenters and more labor.

- Time-Consuming: On-site construction extends timelines.

- Material Waste: More cutting leads to more unused wood.

Understanding the Truss-Built Roof

Truss-built roofs are pre-engineered in a factory. Trusses are then shipped to the site ready to install. They are made with triangular units that allocate weight evenly. These units offer strength and support using fewer materials. Truss-built systems are popular for modern home and commercial builds due to their efficacy and uniformity.

Pros of Truss-Built Roofs

An estimating firm would often prefer truss-built systems for easier budgeting and reduced project risk. Trusses come with several major benefits.

- Faster Installation: Pre-built components save time on-site.

- Cost-Effective: Less labor reduces the overall expense.

- Strong Structural Support: Perfect for large spans without needing interior walls.

Cons of Truss-Built Roofs

Nevertheless, there are some limitations to it. If you predict design changes during the build, trusses may not offer the flexibility you want.

- Limited Customization: You are restricted to standard shapes.

- Transportation Issues: Large trusses require special handling.

- Difficult On-Site Adjustments: Once built, modifying a truss is tricky.

Comparing Cost Factors

Now let us talk about numbers. Cost plays a major role in the Stick-Built vs. Truss-Built Roof decision. Stick-built roofs usually cost more in labor. For custom fitting and cutting, you need to hire someone technician. The cost for stick-built roofing on a medium home is about 10–15% higher than that of truss roofs. Building a truss roof is both easy on labor and cheap in materials. Since they are manufactured in a controlled environment, waste is reduced. In addition, fewer workers are required for installation.

Labor and Installation Time

Another big difference is installation speed. Stick-built projects take more time because everything is built from scratch. Depending on the size, it can take a week or more just to frame the roof. Truss-built roofs, on the other hand, can be installed in a single day once delivered. This is a huge benefit in areas where the weather can delay work.

Durability and Performance

Both types offer strong performance when installed properly. However, trusses are designed using precise calculations, often with engineering stamps, ensuring optimal load bearing. Stick-built roofs rely on carpenter skill and experience. While they are strong, there is more room for error in execution. When it comes to long-term reliability, truss-built roofs have an edge due to their engineered consistency.

Environmental Considerations

Looking for sustainability? Truss-built roofs generate less material waste, which makes them more environmentally friendly. Stick-built systems, due to manual cutting, produce more off-cuts and waste. Nevertheless, you can still make excellent frames if you work with recycled wood or save scraps. If you want to go green, trusses installed on your roof may be your best choice.

Which Type Should You Pick?

What your project needs will guide you in choosing whether to use stick-built or truss-built roofing. Go stick-built if you want custom architecture and can afford longer build times. Choose truss-built if you need speed, cost-efficiency, and structural consistency. Whatever your choice is, always consider the complexity of your roof plan, budget constraints, and timeline.

STILL CONFUSED ABOUT YOUR STICK-BUILT VS. TRUSS-BUILT ROOF CHOICE? CONSULT OUR EXPERT ESTIMATORS FOR ACCURATE COST BREAKDOWNS AND SMART CONSTRUCTION STRATEGIES!

Final Thoughts

The debate of Stick-Built vs. Truss-Built Roof boils down to priorities, flexibility versus efficiency. Each has a clear place in modern construction. Knowing their pros and cons will help you avoid surprises down the line. If your design requires detail and on-site customization, a stick-built roof is your match. If budget and timing are top concerns, then truss-built wins. However, do not estimate costs blindly. Reach out to professionals who specialize in roofing estimation. With the right help, you will stay within budget and build smarter. The best roofing decision starts with a clear understanding and ends with precision.